Global Supply Conditions And Capacity Distribution

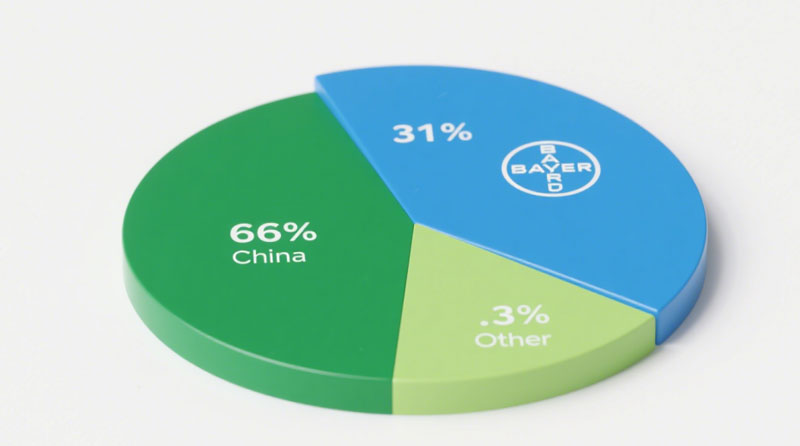

Glyphosate is the world's largest herbicide variety, with highly concentrated production capacity distribution. According to the latest market data, as of 2025, the global total production capacity of glyphosate is approximately 1.2 million tons per year, mainly distributed in China and the United States. Among these, China's production capacity dominates, reaching 810,000 tons per year, accounting for about 66% of the global total. Overseas production capacity is primarily dominated by Bayer (formerly Monsanto), with a capacity of 380,000 tons per year, representing approximately 31.4% of the global total. The remaining small amount of production capacity is distributed in the United States (Abbot Laboratories) and India, totaling less than 50,000 tons per year, accounting for about 4%.

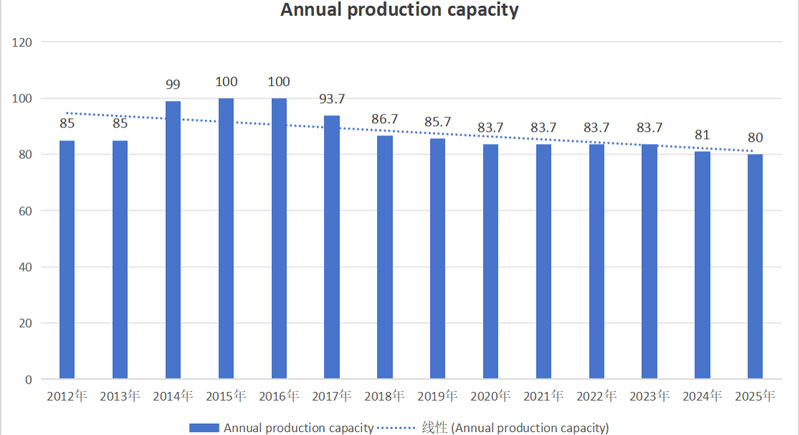

China's domestic glyphosate production capacity remains highly concentrated in the hands of a few large enterprises. Due to China's continuous environmental inspections, safety checks, and supply-side reform policies since 2015, a significant number of small and medium-sized production capacities have exited the market. Only 18 domestic facilities can operate normally, while the rest have remained idle for a long time and are unlikely to resume production. Since 2018, there has been almost no new global glyphosate production capacity added. China's effective glyphosate production capacity has stabilized at around 800,000 tons, with industry expansion primarily driven by technological upgrades.

Glyphosate Industry Chain

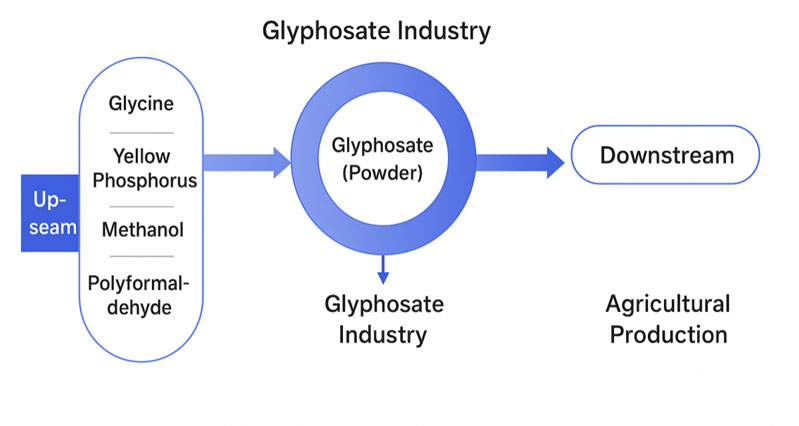

The value distribution within the glyphosate industry chain remains highly uneven, spanning multiple upstream raw material sectors and mid-to-downstream segments. Overcapacity and intense competition have squeezed profit margins in active ingredient production. In contrast, formulation processing and distribution channels—being closer to end markets and leveraging brand value—typically enjoy more stable profitability. Companies with integrated supply chain capabilities (such as industry leaders that self-supply glycine and yellow phosphorus) often demonstrate significant competitive advantages, achieving gross margins for glyphosate products that exceed industry averages.

Production Technology Introduction And Comprehensive Comparison

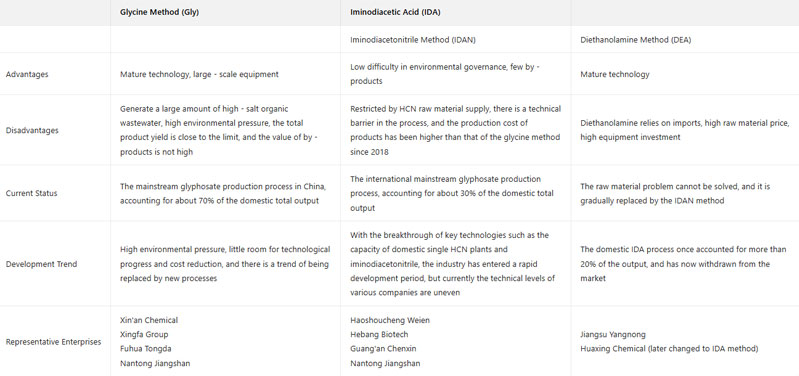

The profitability of the production process of the original drug depends to a large extent on the production process and its comprehensive cost. Next, we will introduce the current mainstream glyphosate production technology and compare its advantages and disadvantages. The industrial production of glyphosate can be divided into two main categories: glycine method and imino diacetic acid (IDA) method. These two processes are significantly different in terms of raw material source, reaction steps, environmental impact and economy.

Glycine (Gly) Method

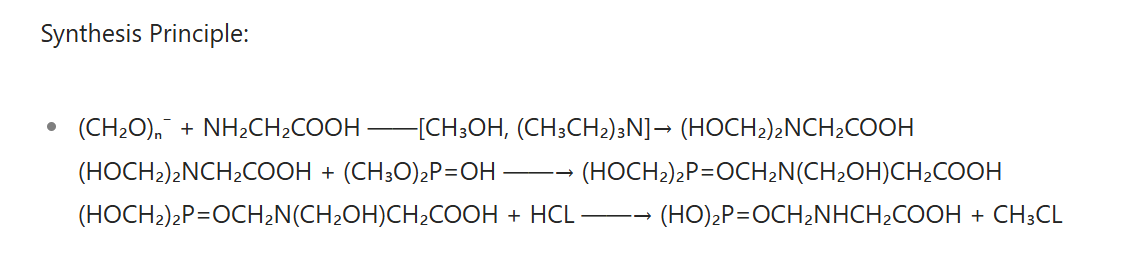

The glycine (Gly) method was industrialized in 1986, and the production process is mature at present. The main raw materials are glycine, phosphorous acid, polyformaldehyde, methanol, etc. The synthesis of glyphosate is completed by three chemical reactions.

The Imino Diacetic Acid (IDA) Method

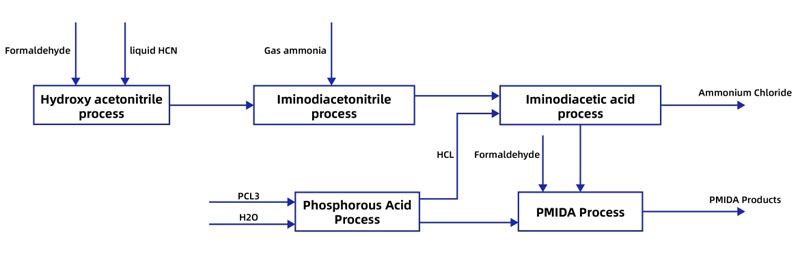

The imino diacetic acid (IDA) process was developed in the late 1990s to produce glyphosate from natural gas and has been industrialized. The IDA process uses natural gas as the starting material and completes the synthesis of glyphosate through four chemical reactions.

advantages and disadvantages

After over a decade of continuous development, China's production technology for glyphosate via the imino diacetic acid (IDA) route has achieved high maturity with a well-established supporting industry. In recent years, significant technological advancements have been made in the IDA-based glyphosate process, progressing from the hydrogen cyanide step and imino diacetic acid step (acid method) to the synthesis technologies for both diisopropyl phosphate (DIPN) and glyphosate. The equipment for each process has gradually achieved continuous and large-scale production, now demonstrating cost advantages over the glycine method. Both industry experts and environmental authorities are optimistic about the future of the IDA-based production route. Through continuous technological R&D and expertise accumulation, DODGEN has achieved breakthroughs in the process technology for key synthesis steps of glyphosate via the imino diacetic acid (IDA) method. Leveraging DODGEN Chemical's capabilities in designing and manufacturing high-end chemical equipment, along with its robust engineering design team, the company has developed an integrated innovation optimization solution for the entire industrial chain of glyphosate production using the IDA method.

DODGEN PMIDA Diagnomethane Process Technology

Technical Highlights

01 Hydroxyacetonitrile Synthesis

The continuous production scheme of hydroxyacetonitrile synthesis using D-AMERT reaction technology was adopted. The product quality of hydroxyacetonitrile was stable and the yield was increased by 2-3%.

02 Synthesis of Iminodiacetonitrile and Iminodiacetic acid (IDA)

The conversion rate of acetonitrile hydroxide was increased from 92% to 95% and the selectivity was increased from 86% to 92% by optimizing the tubular reactor. Using the acid decomposition process, liquid alkali is no longer used to produce imino diacetic acid (IDA), and the yield of imino diacetic acid (IDA) reaches more than 95%. At the same time, the construction cost and operation cost of ammonia recovery device can be avoided in the traditional route of imino diacetic acid (IDA). The phosphorous acid preparation device was added. The phosphorus trichloride was hydrolyzed to obtain phosphorous acid and hydrochloric acid. The phosphorous acid was used for PMIDA glyphosate synthesis, and the hydrochloric acid was used for imino diacetic acid (IDA) synthesis. In the production process of diacetic acid (IDA), there is no flash evaporation wastewater and no multiple concentration of mother liquor, only the by-product ammonium chloride is produced, which completely solves the environmental protection problem.

03PMIDA Synthesis

The PMIDA diaphosphate was synthesized from imino diacetic acid (IDA) and phosphorous acid. Because the PMIDA diagnosine mother liquor does not contain salt, the mother liquor can be recycled almost indefinitely, and the whole PMIDA diagnosine synthesis does not produce high-salt organic wastewater.

Process Profile

The synthesis of PMIDA dihydrogen phosphate consists of five processes, namely, hydroxy acetonitrile process, imino diacetonitrile process, phosphorous acid process, imino diacetic acid process and dihydrogen phosphate process.