Static Mixer

Static mixing technology is an advanced and high-efficiency pipeline mixing technology. By installing specially designed stationary mixing units inside the pipeline, the fluid flowing through is continuously divided, rotated and recombined, thus achieving rapid and uniform mixing, reaction, heat transfer or dispersion.

⬆ Click to watch the video DODGEN Static Mixer

Equipment Types

The mixing of different gas-liquid/liquid-liquid materials is by no means a one-size-fits-all approach. We have customized a variety of mixer models for materials with different properties:

01 DODGEN DSV Model

The mixing element of DODGEN DSV is a cylinder composed of multiple corrugated plates of specific specifications, which can also be made into cones, cubes, cuboids and other shapes. Especially for mass transfer between heterogeneous fluids, DSV has extremely strong adaptability.

The DSV static mixer is usually used in the absorption, mixing and reaction processes of gas-gas, gas-liquid and liquid-liquid materials with low viscosity (viscosity ≤ 10² cp), and is particularly suitable for mass transfer between clean media.

02 DODGEN DSX Model

The mixing element of DODGEN DSX is formed by welding unit plates intersecting at a certain angle, which is suitable for large flow rate, large viscosity ratio and complex working conditions.

The DSX static mixer is usually used in the mixing and reaction processes of gas-liquid and liquid-liquid media with medium and high viscosity (viscosity ≤ 10⁴ cp), featuring a wide application range and high mixing uniformity.

03 DODGEN DSXL Model

The mixing element of DODGEN DSXL is made by welding unit plates intersecting at a certain angle. Its structure is specially designed for high-viscosity system working conditions, and it is often used in the fields of polymer mixing, heat exchange, devolatilization, etc.

The DSXL static mixer is usually used for heat transfer, mixing and forced heat exchange of materials with high viscosity (viscosity ≤ 10⁶ cp) and polymer materials.

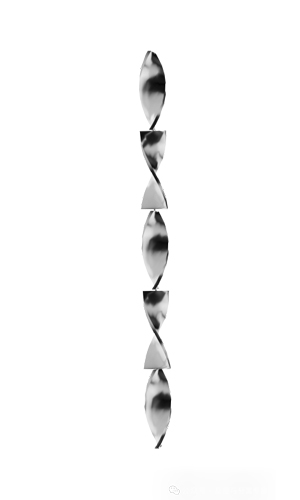

04 DODGEN DSK Model

The mixing element of DODGEN DSK has a wide application range and is not easy to be blocked. It is made by cross-welding rotating plates twisted at a certain angle left and right at 90°, and is often used in working conditions with relatively low mixing requirements.

The DSK static mixer can be used in the mixing, reaction and heat transfer processes of liquid-liquid and solid-liquid materials with a wide viscosity range, and is especially suitable for viscous media with small flow rate and impurities.

Project Cases

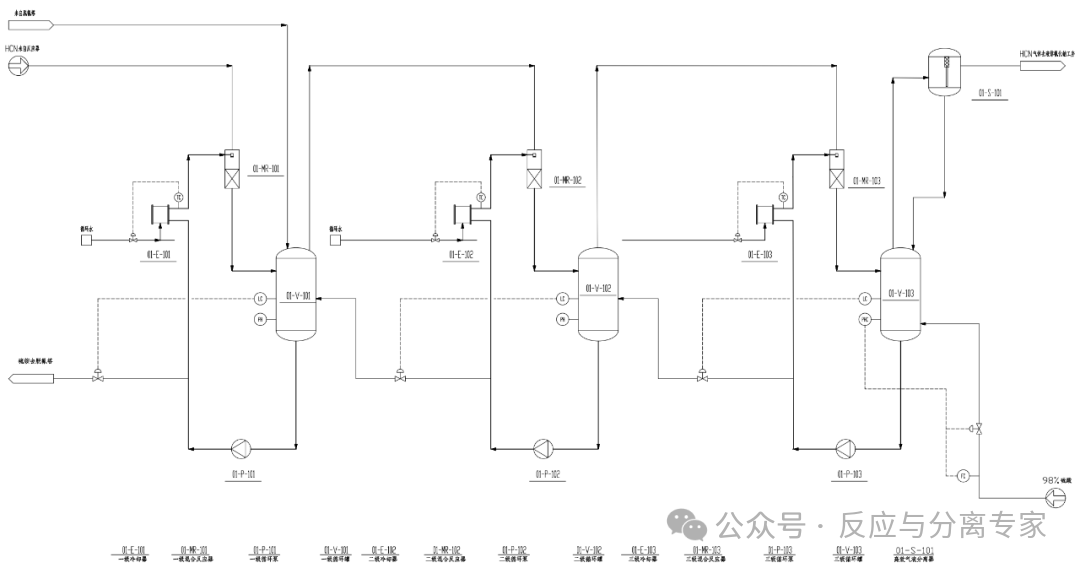

Hydrogen Cyanide Deamination Project – Achieving Space Reduction

The customer's hydrogen cyanide project once faced such difficulties: the traditional deamination process used a deamination tower with a diameter of 1000 mm and a height of about 20 m, which had high equipment cost, unstable deamination effect, severe equipment corrosion and difficult maintenance. After DODGEN adopted the multi-stage static mixing system, the length of the deamination equipment was shortened to less than 5 meters, the floor area was reduced by about 70%, and the deamination efficiency was increased by about 30%. In the customer's words: "DODGEN not only solved the technical problems, but also optimized the plant layout by the way."

Liquid Sodium Cyanide Project – Achieving Selective Absorption

In the production of liquid sodium cyanide, how to achieve precise selective absorption of hydrogen cyanide while minimizing carbon dioxide absorption? Traditional methods were difficult to achieve selective absorption, resulting in excessively high sodium carbonate impurity content in the product. Through precise calculation of the quantity and arrangement of mixing units, we designed a mixing system with "molecular recognition" function, which ultimately greatly reduced the content of sodium carbonate impurities in the liquid sodium cyanide product.

Application Scenarios

01 AbsorptionFrom

Carbon capture on offshore platforms to desulfurization and denitrification in chemical plants, it has higher efficiency than traditional tower equipment, but only occupies 1/10 of the floor area.

02 ReactionIt

Achieves rapid reaction and precise temperature control, avoids side reactions and improves product purity.

03 Heat ExchangeIt

Realizes uniform heating or cooling of high-viscosity materials and avoids local overheating.

04 DispersionIt

Precisely controls the droplet or bubble size of gas-liquid/liquid-liquid dispersion, and its research can predict the dispersion effect under specific process conditions.

DODGEN Advantages

Calculable Mixing

We can accurately predict the concentration distribution, temperature curve and reaction progress after mixing.

Customizable Solutions

From single-stage application to multi-stage series connection, and from normal temperature and pressure to high temperature and high pressure, we can provide optimal solutions.

We offer a full-process service covering process diagnosis → unit selection → flow field simulation → structural design → manufacturing and delivery → installation guidance.

More importantly, we have established a mixing parameter database and accumulated successful experience from hundreds of projects over the past decade. When you put forward your needs, what we provide is not just a drawing, but a complete set of verified engineering experience.